Machining assistance solutions

Cryo machining: MPM and its partners provide a complete milling and turning solution under the CRYO7 ® brand.

The main purpose of lubrication during machining is to cool the cutting area. The user can obtain several advantages by replacing conventional lubrication with a cryogenic liquid:

The patented technology is deployed in industrial production on parts with high added value. MPM can transform your existing resources or deliver a new machine equipped and tested on our platform.

The technical environment of the machine is also reviewed in order to integrate all the safety features and systems. MPM offers service contracts for the maintenance and inspection of equipped machines.

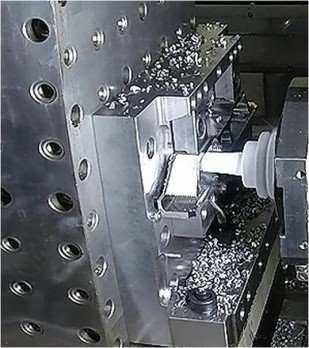

Cryogenic milling:

A preliminary study can confirm feasibility and define all the modifications needed to integrate spindle-centred cryogenic assistance.

Cryogenic turning:

According to your machine types, MPM provides quick connection/disconnection solutions for the cryogenic fluid with the turret, the tool clamping modules, or the tool holders, according to the case.

Tests / Cryogenic feasibility:

MPM can support your feasibility testing using our dedicated R&D resources or based on those of our partners (turning, 3 to 5-axis milling).