Adiabatic shearing presses

Adiabatic shearing is the primary industrial application of our machines. The impact they deliver is like a ‘karate chop’ that separates a long product, in a fraction of a second, into precise segments, without burrs, and with a high cut quality.

ADIAPRESS ® shearing presses are modern, high-performance production tools. They require no lubricants, provide very high frequencies, and are very flexible. A tool change to switch from one production run to another satisfies SMED expectations.

These shearing presses can be used to cut:

The lengths to be sheared (at least the diameter) are perfectly variable and configurable thanks to the human-machine interface. The same applies to all the production parameters: frequency, management of bar ends (start and end), quantities, etc. The length precision is typically +/- 0.05 mm because of the lower deformation due to the precision of the feed systems.

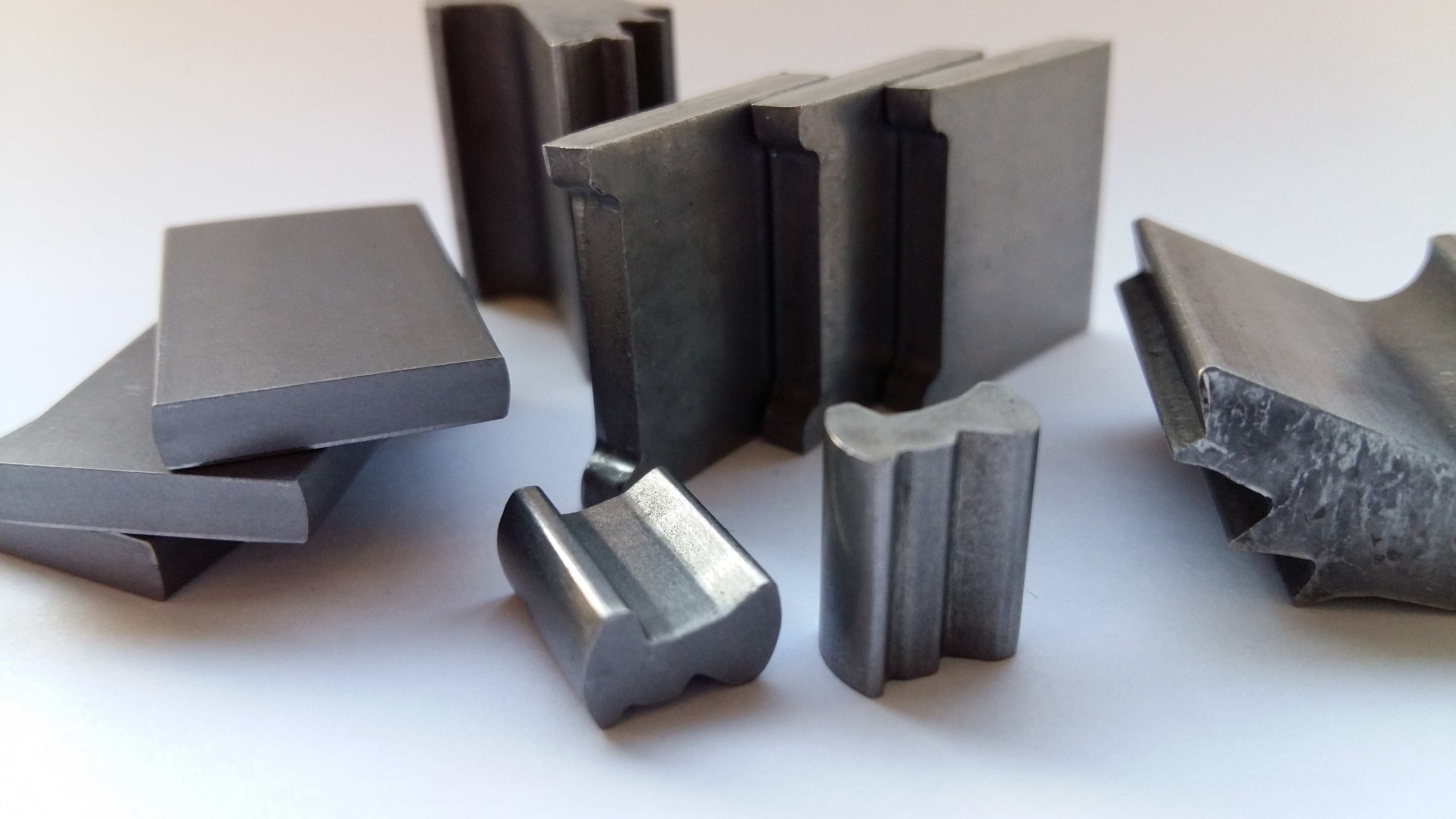

The cutting tooling simply consists of two prismatic blades equipped with a central hole in the shape of the product to be sheared. These cutting blades have a very long working life thanks to their design and their ability to be sharpened by simple flat grinding.

ADIAPRESS® designs and develops standalone adiabatic shearing machines or integrates them with commercially-available peripherals that are useful for production from bars (bar loading magazines, bar loaders) or spools (dispensers, rectifiers).