Vertical lathes

We offer vertical lathes in diameters from 1000 to 6000. They are perfectly suited to machining steels and hard materials (titanium, Inconel, etc.).

The machine structures are very rigid bases (stabilised castings) equipped with precision guiding systems. The kinematics of the axes are based on pre-loaded ball screws coupled to brushless motors and precision external measurement rules. The next-generation numerical controls incorporate the safety features and pages to suit your production and maintenance needs.

We design the drive kinematics and platen guiding systems (standard or hydrostatic guides, direct drive, etc.) according to your production needs (speed, torque, power).

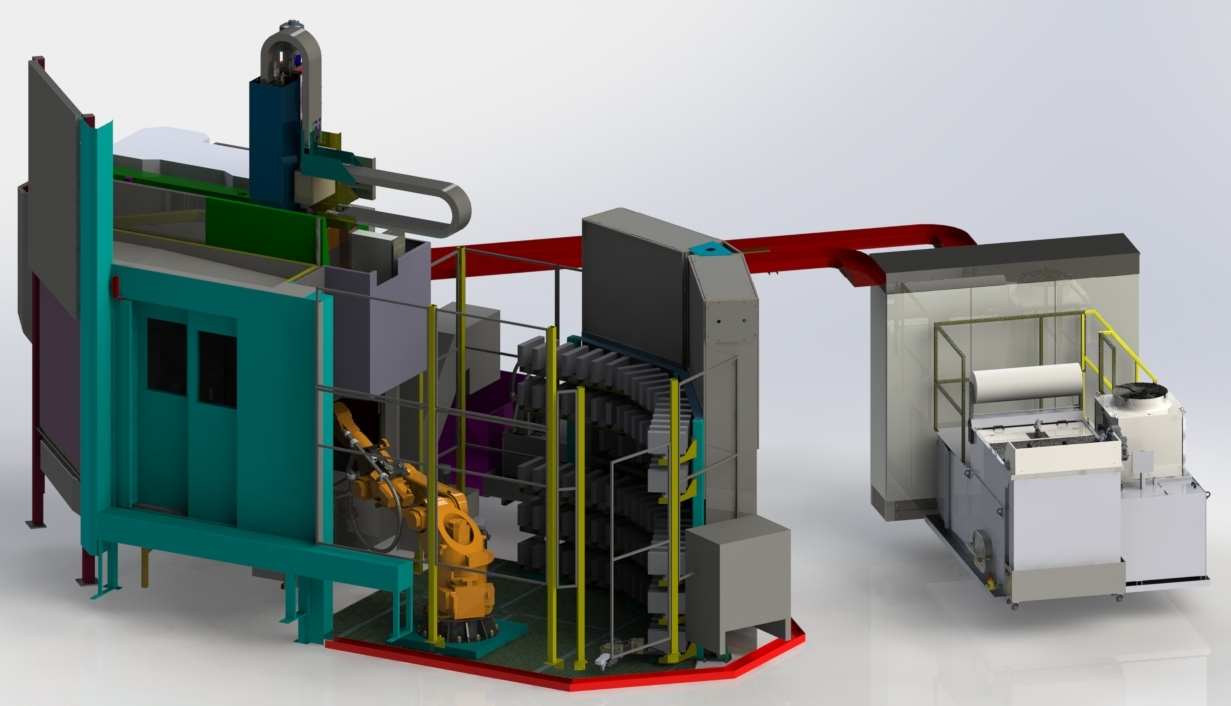

According to their configurations, the lathes can be palettised. We personalise the machine according to your need: number of pallets, preparation station, waiting station, manual or automatic palletisation for lone machine or machine integrated in a cell, clamping types (manual or automatic) on the platen, etc.

Lathes can be supplied with one or two rams incorporating the latest turning, milling, tool centre lubrication (high-pressure spraying up to 400 bar), cryogenic assistance, tool clamping (horizontal, vertical, combined), accessories (electrospindle, special head, etc.).

Lathes are equipped with a casing to suit the technologies and your environment (installation location, production constraints). We offer you different tool magazine solutions (disk(s), chains + manipulator, robotic with large capacity rack: 100 tools, or more on request). For more details, refer to the “Tool Magazines” page of our “System and Peripherals” catalogue.

MPM adapts perfectly to your specific needs, thanks to its wide experience on different types and applications of vertical lathes.