Home \

Powdered materials

Powdered materials

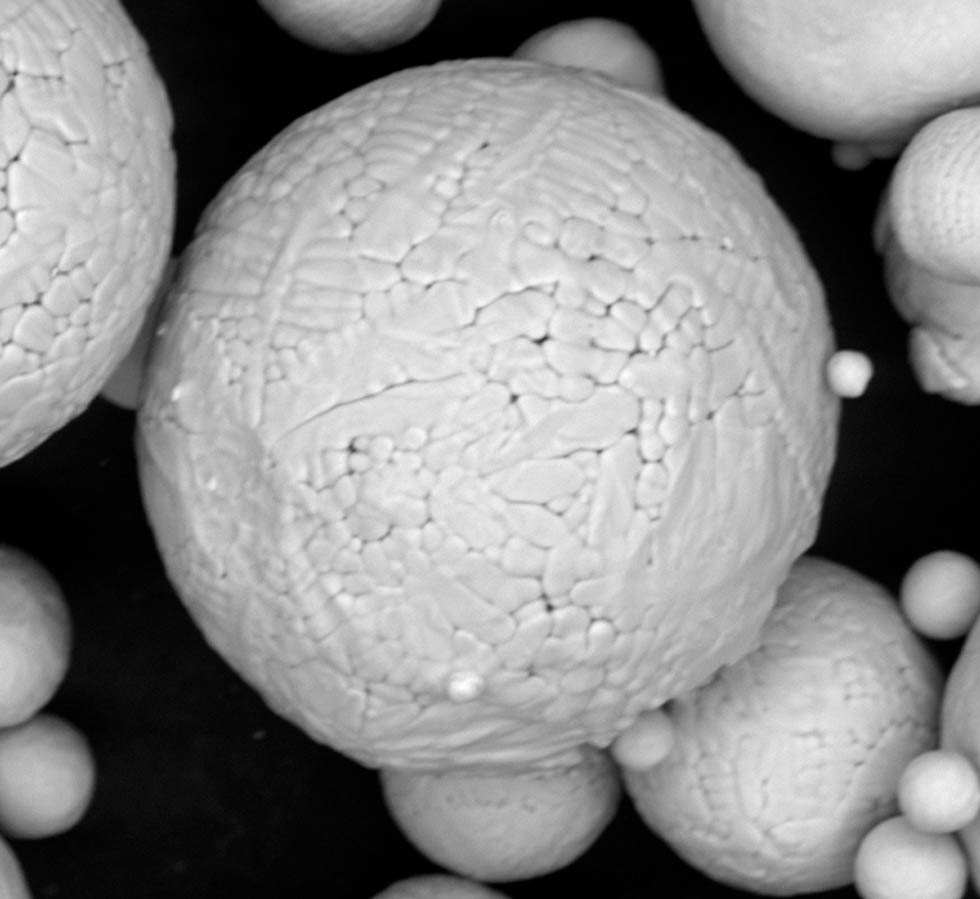

The manufacture of parts from powdered materials is definitely the most economical way to proceed. In addition to the economic advantages of powders, they offer enormous technical possibilities in terms of:

- Availability and composition:

Many metals, such as alloyed and stainless steels, aluminium, copper or titanium alloys, etc., are available in this form. This also applies to the semi-crystalline technical polymers that are much appreciated in aeronautics, the chemicals sector, biomechanics, etc., and technical ceramics such as alumina, zircon, etc.

In addition, the diversity of production processes (atomisation, shredding, reduction etc.) makes it possible to imagine new mixtures and alloys to satisfy needs that are sometimes antagonistic (hardness/resilience; magnetic/insulating, etc.).

Additive manufacturing is the most revolutionary process in the category. It provides the potential to manufacture any solid or hollow 3D shape, with remarkable surface and volume effects (lattice structures). Hot or cold isostatic compression is also capable of producing very interesting geometries, including for medium-sized or large parts.

For simpler geometries (that can be demoulded axially), uniaxial compressing in a press, which is the most productive by far (approximately 10 parts per minute), generates high-precision and high-quality surface finish parts like the necessary compression tooling.

Because powders by definition have a smaller particle size compared to conventional materials (bars, sheets or plates), they constitute the best, if not the only, way to obtain ultra-fine microstructures that can display the highest level of mechanical properties.

Manufacture from powder can also be employed to obtain certain isotropic properties, mass, etc. MPM offers a range of premium-quality metallic powders thanks to its ultra-modern gas atomisation process.

MPM completes this offer by providing presses and machine tools suitable for the manufacture of high-performance parts from powders. Our adiabatic presses are essential for the creation of parts via the SCANPAC® process. Moreover, our dedicated machining equipment and our innovations (cryo-machining) can respond to finishing needs after pressing and sintering, and after 3D printing.

“Welcome to the metallurgy of the future“