Solutions

The fruits of our research and development enrich our product offer and bring value for our customers.

- VAMS: Video Assisted Machine Support is a remote maintenance system that combines remote control and video, so that troubleshooting or advice on our machines can be dispensed immediately.

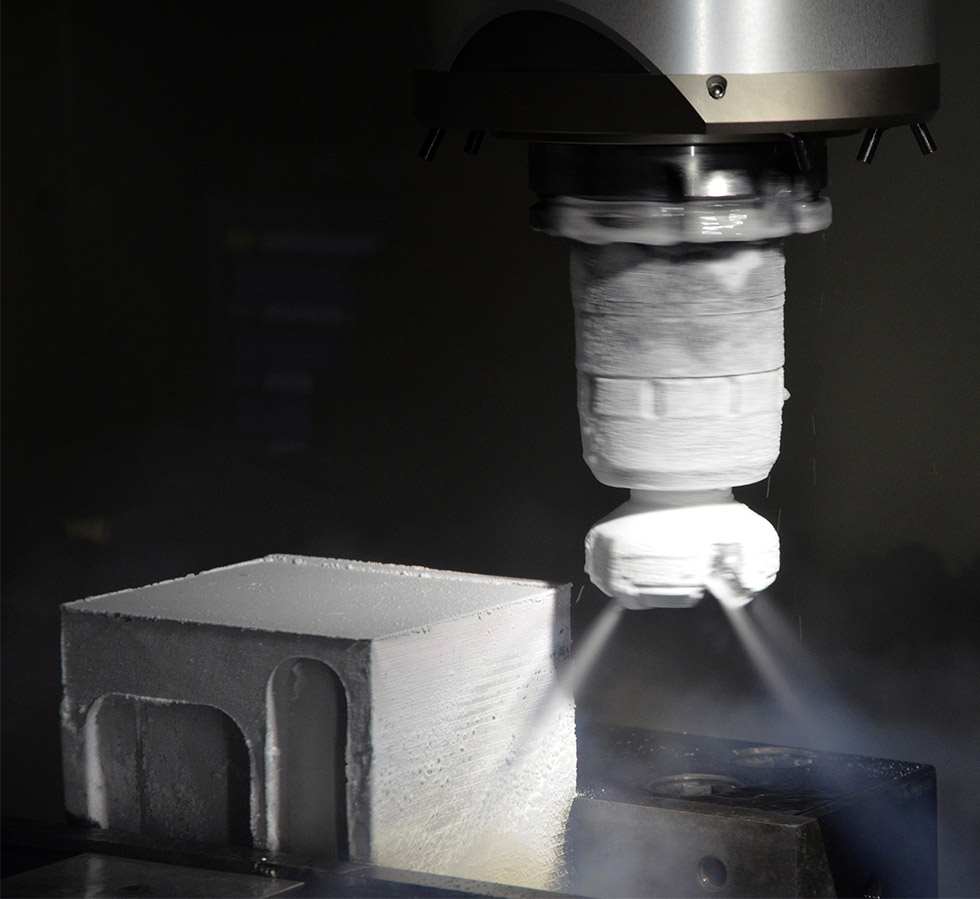

- Cryo machining: Replacing classic cutting fluids with a cryogenic fluid drastically improves the machining performance of hard materials such as titanium (tool working life, cutting speed). MPM and its partners provide a complete milling and turning solution under the CRYO7 ® brand.

- Shaving: This adiabatic cutting technique can drastically improve the finish of cutting surfaces, typically reaching Ra values from 0.2-0.3 µm.

- Tube shearing: The feasibility of tube shearing has been proven, which saves material, avoids the intrusion of shavings inside tubes (and therefore also costly washing procedures), the risk of circuit pollution, clogging, etc.

- 3D sawing: It is already a real revolution for aerospace structural parts machined from bulk aluminium. In fact, thanks to this technology, the material component of the part cost is halved! The technology should apply to other materials, and particularly expensive materials.

- Eco Efficiency: Three years of R&D have proven that it was possible to reduce the energy consumption of machining centres by 30%, which is a substantial saving in operating costs. The best practices arising from this project will be used in the design of our machines and implemented in the context of our reconstruction projects.